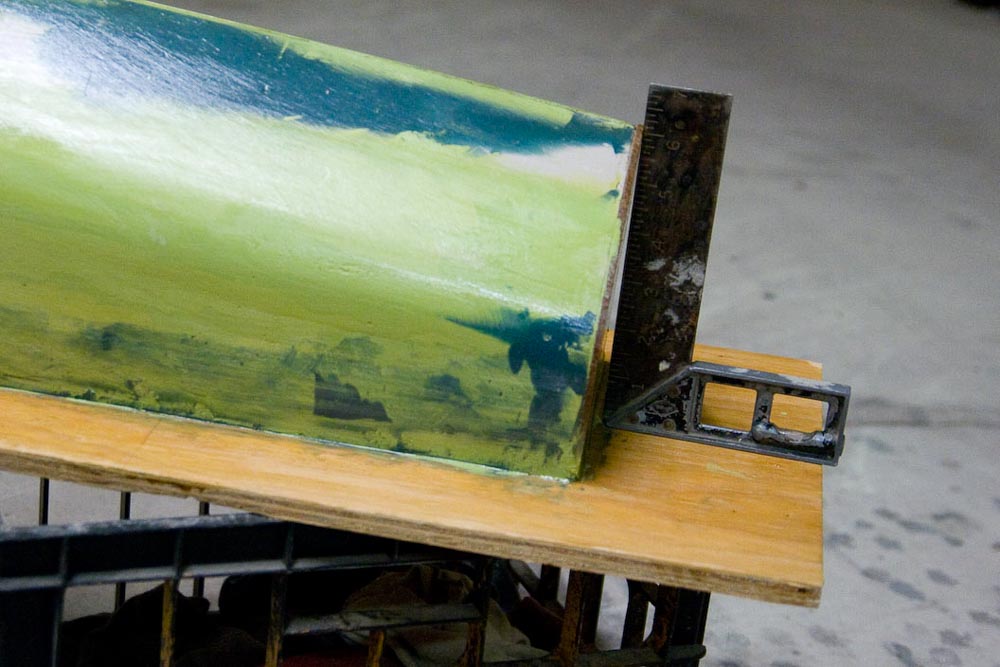

3/17/2012 to 4/30/2013. Front surfaces are looking pretty good. It’s time remove out the headlight cover models and make molds for clear covers. I found a fellow online, Mark Clapp, who makes clear covers, and he agreed to make a set of covers if he could keep the molds. He ended up making three sets, because the leading edge was too soft. The last set is pretty good. So that’s the next step. First step was to make fiberglass replacements for the models. Then I had to make the mold undersized to compensate for the thickness of the polycarbonate, so I used shower liner material from Home Depot to bring in the surfaces. The gray stuff on big rolls by the fiberglass shower units. It had to be pretty flexible because the surfaces are compound. Not very elegant, but it worked. The surfaces of the covers are really pretty straight forward. I modeled them in Rhino3D and could have had parts grown or milled, but that sounded like it was probably out of my budget.

Leave Comment